Manufacturing The Future

Expanding the technological bounds of humankind with iCOMAT, Blueground acquires startup in Brazil, jobs, product culture, Netflix & neural networks, events, and more

This newsletter is about startups and technology. We look into bold teams that solve challenging problems, explore tech trends, learn startup lessons, and find out what matters in Greek tech. Subscribe below, join 4,235 others, and come aboard.

You can find me on LinkedIn and Twitter.

-Alex

Manufacturing The Future

Today, I’m really excited to chat with Evangelos Zympeloudis, CEO & co-founder of iCOMAT, a University of Bristol spin-out that revolutionises how we manufacture rockets, cars, aircrafts, and other vehicles, with lightweight materials. This is a hardcore advanced manufacturing startup, able to propel industrial and technological progress by taking advantage of the unique benefits of composite materials. The team is split between Bristol, UK and Athens, Greece, and backed by Velocity Partners.

We learn:

why lightweight vehicles are the answer to faster and cheaper transportation, and reduced CO2 emissions

how composite materials and carbon fibre can reverse the degrowth in multiple industrial domains

why we cannot manufacture lighter vehicles with the technologies we currently have, and how iCOMAT aims to change that

latest trends in space technology

state-of-the-art methods in advanced manufacturing and 3D printing

Let’s get to it!

Evangele, it’s a pleasure to talk to you today! I’ve wanted to do this chat for some time now because what you’re building can be truly game-changing for technological progress — progress that has somewhat fallen short in multiple industrial domains when tracked against the lofty hopes of the 1950s & 1960s.

EZ: Thanks for having me Alex! Very happy to chat with you.

Let’s consider the most literal instance of non-acceleration: We are no longer moving faster. Take, for example, the travel time across the Atlantic which, for the first time since the Industrial Revolution, is not getting much shorter (after decommissioning Concorde in 2003).

EZ: You’re right. When it comes to vehicle performance (cars, planes, etc) there have been mostly incremental improvements in the past decades. But I think we’re now going through a period where many things we took for granted are about to change! Mobility, in particular, is on the cusp of acceleration. The speed of transportation is about to increase, while the cost of transportation and CO2 emissions will go down.

The answer lies in reducing the weight of vehicles. A lighter vehicle can move faster while it requires less energy. Lightweighting is, in fact, one of the most powerful ways to reduce emissions whether we talk about cars, planes, etc. Bill Gates once said, “The more weight you're trying to move, the more batteries you need to power the vehicle. But the more batteries you use, the more weight you add, and the more power you need”. It’s a viral loop right there. If you look at the automotive industry, the weight of cars has gone through the roof recently. We add larger batteries (in electric cars), more sensors for autonomy, things for modern-day comfort, etc. Sometimes, the weight has reached even close to three tons for SUVs. Not only do we require much more energy to move, but also the production cost is higher.

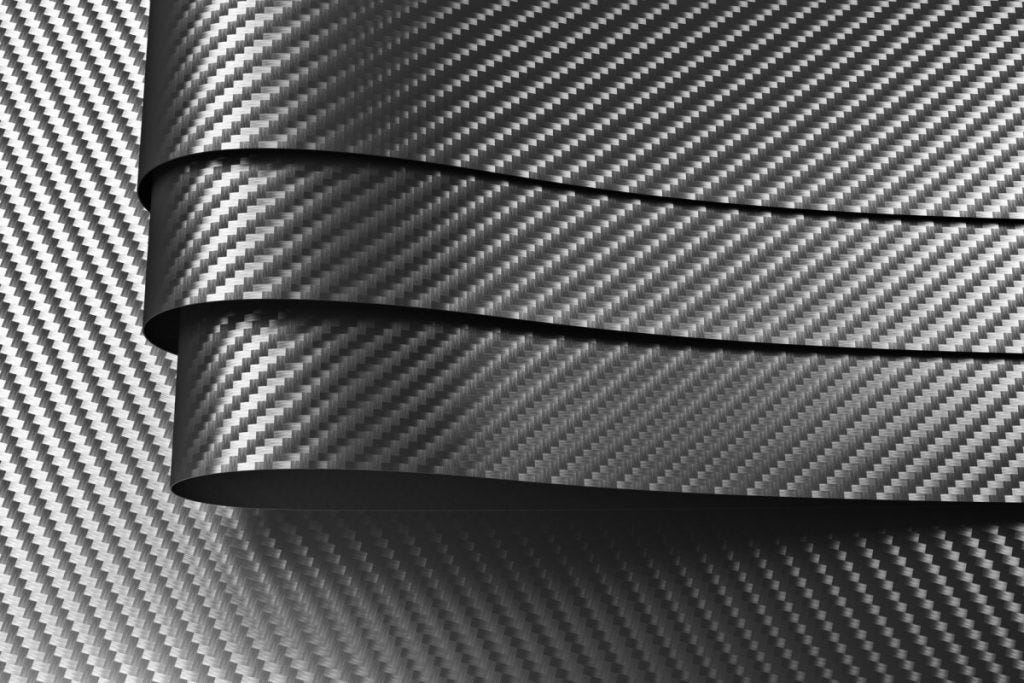

The aeronautics industry has already found an answer — using composite materials such as carbon fibre in aircraft construction. Carbon fibre is a byproduct of petroleum, which is stronger than steel and lighter than paper. We’re talking about millions of very thin strands of carbon (thinner than human hair) that are glued together with resin. This composition gives it superhero strength. Basically, in anything that flies: planes, urban air mobility aircrafts, rockets, etc, we have been replacing metallic components with carbon fibre for years. Its production cost is much much higher though, which currently makes it impractical to use to a wider extent.

As a society, we’ve now reached the point where we need faster, cheaper transportation that is environmentally sustainable. What this requires is lightweighting beyond the technologies we have to date. If we go back to the late 1800s / early 1900s, we were at a crossroads too. We had the Industrial Revolution, and people wanted to move goods rapidly across locations. Then, the railways were introduced which were made possible by the use of steel. If we can draw an analogy, at that time, steel was like carbon fibre today — a niche, very expensive material. Then, people like Bessemer and Carnegie came along and improved and commercialized steel production (Carnegie's company was the most valuable company globally back then). They gave us steel, and steel gave us railways to move faster, skyscrapers to manufacture higher buildings and address urbanization, and propelled a new wave of technological progress. These changed the history of humankind. I think a similar revolution will happen with composite materials, enabling the world’s lightest cars, planes, spacecrafts, etc. This is the revolution we enable with iCOMAT.

You said lighter vehicles will revolutionise the way we move. If we zoom in here, which are the mobility industries where this can have the larger impact?

EZ: I think we can divide them into two large groups. First, the more “traditional” industries such as automotive and aeronautics. The global population is rising and we’re going to need a lot more vehicles for transportation in the next decade. Both industries face pressure to reduce CO2 emissions, become more cost-efficient, and increase the speed of production. Yes, they both go through transformation phases now — automotive disrupted by electrification and aeronautics experimenting with new concepts such as hydrogen fuel cells. But I believe this is not enough and lightweight materials can really help here.

Second, we have the “emerging” industries: space and urban air mobility. New investments are flowing in and the interest is picking up, particularly in space, as the cost of sending things into orbit is constantly declining. In a nutshell, producing lighter rockets is game-changing. By reducing the weight of the rocket’s structure by 1kg, you can send 1kg extra payload to space. You save weight from the structure and you can send more satellites, space probes, or spacecrafts carrying humans or cargo. Obviously, this can drive space tech innovation and space exploration. The same applies to urban air mobility — creating lighter vehicles means we can add more passengers, fewer batteries, etc.

All in all, this is a one-way street. The incentives are clear: faster and cheaper transportation, and fewer emissions.

So, since using lightweight materials to manufacture lighter vehicles is such a clear-cut decision, why isn’t this more prevalent already?

EZ: Because we have reached the limits of what we can do with the technologies we have in our hands. Production costs are very high nowadays. Think that in automotive, carbon fibre is used only in supercars in the likes of Ferraris and Paganis. Carbon fibre is expensive as a material and, to make things worse, we use more raw material than what’s necessary during production — layers of carbon fibre one on top of the other — shooting production costs through the roof. So far, this was the only way. The reality is that we still don’t have the right industrial technologies to manufacture vehicles from lightweight materials in an effective way. We aim to change that with iCOMAT.

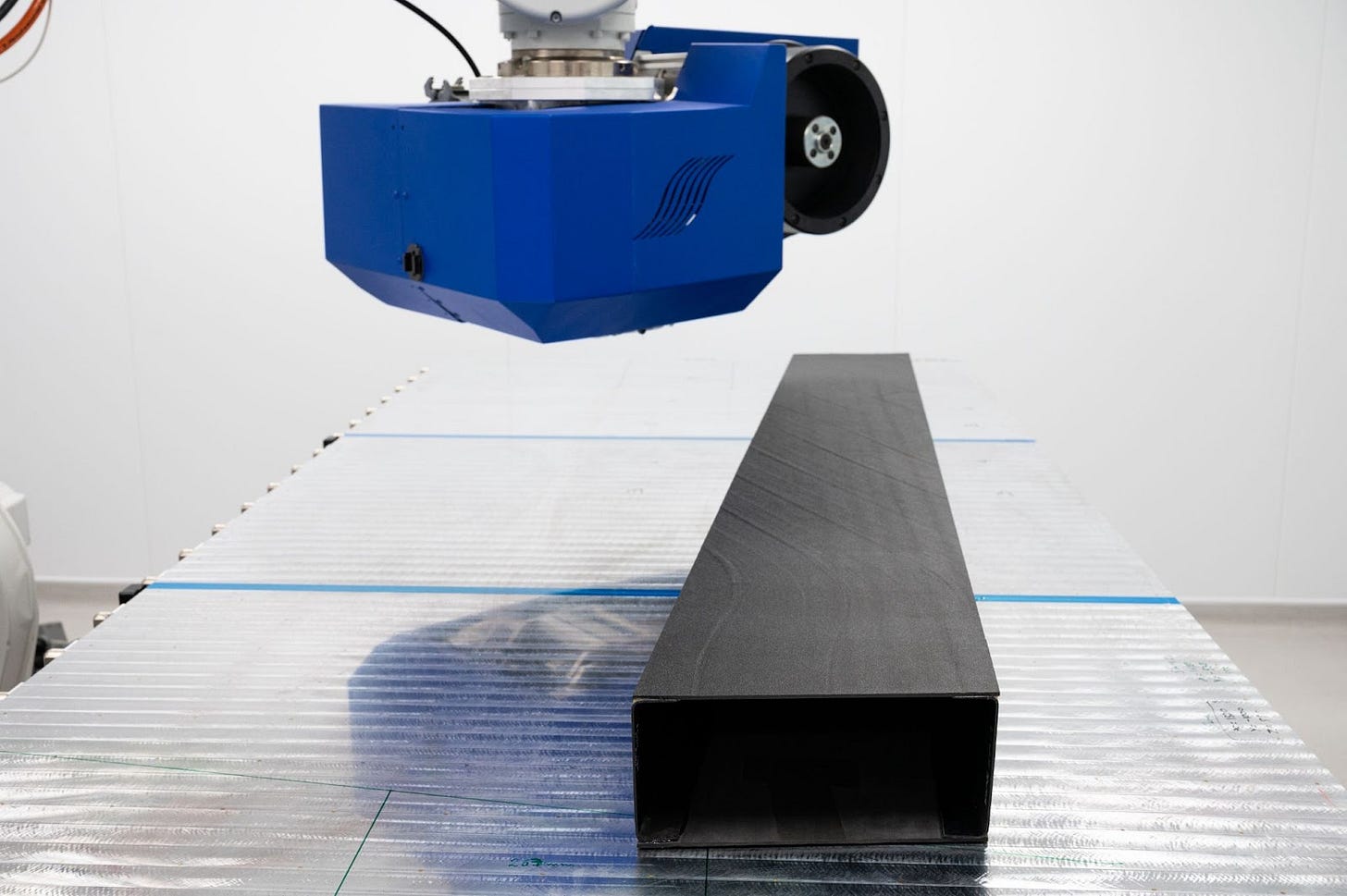

At iCOMAT, we’ve created patented technology based on 10 years of research at the University of Bristol that’s reducing the weight of vehicle components drastically, even up to 65% in some cases. We’re manufacturing lighter vehicles, cheaper and faster, compared to the existing state-of-the-art industrial technologies. We’re working with some of the largest industrial manufacturers to create components for cars, planes, rockets, etc. A couple of names I can disclose are Jaguar Land Rover and the European Space Agency, with more announcements coming out soon. All this is made possible by enabling fibre steering at an industrial scale for the first time. Let me unpack this.

State-of-the-art industrial technologies — how planes are manufactured today — are a bit like robotic sellotape dispensers, but instead of sellotape, they lay carbon fibre tapes. Very good in a straight line, very bad in steering. Remember, carbon fibre is millions of very thin strands of carbon glued together with resin. Hence, the material is strong only in the fibre’s direction. Due to this textile texture, steering (having full control of the placement of material for components with different sizes and shapes) becomes very hard and, in fact, prohibitive with the technologies we had to date. Manufacturers have been stacking fibre layers at different angles to balance the properties in all directions, leading to significantly more raw material used, higher costs, more weight, and more defects. iCOMAT is building the world’s first machine capable of fibre steering.

We also unlock the potential of composite materials by enabling hybrid structures: a combination of high-cost, high-performance composites, e.g. carbon fibre, and low-cost, low-performance material, e.g. steel, metal, aluminium, polymer, etc at a ratio of, let’s say, 10% vs. 90%. We do this by steering the reinforcement carbon fibre directly in the load path of the structure. This is really powerful because we can create components for the more cost-conscious industries such as automotive — components, which can be 30% lighter and 30% stronger, with comparable cost.

I’d like to switch gears for a minute and take a closer look into the space industry. The cost of launching things into space has been on the decline. In fact, the cost of sending 1kg to Lower Earth Orbit has dropped ~95% since 1965. What is the impact of lightweight components when it comes to innovation in space?

EZ: Weight is critical for anything that flies. When it comes to space rocket mass, on average, 8% of the weight is the structure, 2% the payload, and 90% the fuel. There’s SpaceX, which makes more efficient engines that require less fuel, but where we stand today, I think lightweight manufacturing of rockets can have the most significant effect and reduce the cost of sending things into space even further. As the weight of the structure goes down, we’re able to send more payload with every rocket. In fact, a 10% reduction in structure mass can lead to a 40% reduction in launch cost. You can imagine how huge this is for space exploration. If it costs $20 million to launch a satellite, you better make sure that everything is perfect. But if it only costs a few million to get your satellite up, you can test and iterate and experiment much more than you could before.

Moreover, there’s a relatively newer industry called space manufacturing, where companies such as Space Forge and Varda Space send satellites into space to produce tangible goods beyond Earth. They benefit from microgravity and vacuum, enabling the research and production of goods that could otherwise not be manufactured on Earth. The goal is to manufacture revolutionary products in space, pushing the boundaries in areas such as drug discovery, semiconductors, etc, and then bring them back to Earth. In the future, space could be leveraged for economic benefits, too. To make this viable, we need further cost reductions in space tech. Lightweighting can be a powerful tool towards that goal.

Do you see 3D printing — metal or otherwise — replacing wide-scale manufacturing any time soon?

EZ: No. I think it has its place, especially 3D metal printing. You can produce some components, which would be difficult, or actually impossible, with traditional metal casting or metal machining operations. But, it's slow, expensive, and cannot compete with existing processes for volume production. The same goes for 3D printing for composite materials. It can manufacture less than 1kg of material in 1hr, which is two orders of magnitude slower than what we do with iCOMAT machine. In addition, the structural properties are not at the same level as traditional manufacturing. Overall, I believe 3D printing has its place in prototyping, but the holy grail was going into production. And that clearly hasn't happened. There are inherent limitations to 3D printing that cannot make this an efficient way for manufacturing production lines.

What are other state-of-the-art methods in advanced manufacturing that you think can accelerate technological progress?

EZ: Tesla is an example of a company working on some very advanced manufacturing methods. It’s no accident that they have disrupted the automotive industry, and several OEMs are following their steps. For instance, they assemble cars from four or five sections made from aluminium casting.

All in all, I’m confident that we’ll see significant industrial progress in the decades to come. Composite materials will play a key role in this, expanding the technological bounds of humankind. What steel did for the Industrial Revolution, composite materials can do for our generation. It will be the Carnegies and Bessemers of our generation that will enable this future. And we want iCOMAT to have a front seat in this revolution.

Evangele, thank you so much for taking the time, it was great to talk to you!

EZ: Thanks Alex, it was a pleasure!

Startup Jobs

Looking for your next career move? Check out 909 job openings from Greek startups hiring in Greece, abroad, and remotely.

News

Blueground announced the acquisition of Brazilian proptech startup Tabas and is about to launch in the Latin American market, reaching 10,500 apartments in 29 cities globally.

Discovery app for theatre, Stagedoor, was acquired by entertainment company, Trafalgar Entertainment.

Xembly raised $15m Series A to develop an AI assistant for corporate meetings.

13 companies entered the Endeavor ScaleUp program: Plum, Flexfin, Natech, Finclude, Ariadne Maps, TigerAire, Perceptual Robotics, Dyania Health, Thymia, Embion Technologies, Protio, Welcome Pickups, and Wikifarmer.

Startup accelerator, VentureGarden Heraklion is accepting applications until Dec 26.

Six Greek research centres received financial support of €119m from the European Investment Bank.

Interesting Reads & Podcasts

Improving Netflix video quality with neural networks by Christos Bampis, Senior Software Engineer at Netflix, here.

An introduction to startups and Greek tech with Sakis Triantafyllakis, Director of Product Growth at Orfium, here.

A post by Manos Kyriakakis, Head of Product & Growth at Simpler, on how to create an experimentation-driven product culture.

Mikri Kouventa episode with Antonis Kalipetis and Paris Kasidiaris discussing how to maintain team efficiency as a team scales.

Deployment previews on Kubernetes by Andreas Gounaris, Senior Staff DevOps Engineer at Blueground, and Stratos Pavlakis, CTO at Blueground, here.

Do your goals prevent your success? with Caterina Kostoula, Executive & Team Coach, here.

Blockchain tokens and the difference between ERC-20 and ERC-721, from Vladimiros Peilivanidis, co-founder of ONETHER DIGITAL, here.

A podcast with Victor Trokoudes, co-founder & CEO of Plum, discussing lessons learned from his entrepreneurial journey.

A podcast with George Hantzaras, Director of Cloud Platform Engineering at Citrix, on platform engineering, here.

Embrace Risk, newsletter from Konstantinos Livieratos, Senior Software Engineer at Detectify, for reliability engineering practices and culture, scalability, availability and incidents.

Events

“[Hack Session] Scaffolding Projects” by Devstaff on Nov 25

“DevFest Hellas 2022” on Nov 26

“28th Thessaloniki WordPress Meetup” by Thessaloniki WordPress Meetup on Nov 26

“Incorporating Core Web Vitals in Product Development” by Product Community Greece on Nov 29

“A very Fluttering Autumn” by Flutter Greek Community on Nov 29

“Tech Finance Network Xmas event” by Tech Finance Network on Nov 30

“61st Athens Agile Meetup” by Agile Greece on Nov 30

“HR Greece: The road ahead for 2023” by HR Greece on Dec 1

“Kubernetes Athens vol17” by Athens Kubernetes Meetup on Dec 1

“Open Conf” on Dec 2-3

“Greeking Out in New York” by Endeavor Greece on Dec 6

“Open Coffee: Patras” by Open Coffee on Dec 13

“Open Coffee: Ioannina” by Open Coffee on Dec 14

“Securing your Cryptoassets, Proof of Work vs Proof of Stake and social meetup” by Bitcoin & Blockchain Tech Meetup on Dec 15

“MLOps Workshop: The Full ML Lifecycle - How to Use ML in Production” by Athens Big Data on Dec 17

If you’re new to Startup Pirate, you can subscribe below.

Thanks for reading and see you in two weeks!

P.S. if you’re enjoying this newsletter, share it with some friends or drop a like by clicking the buttons below ⤵️